Types Of Ball And Gate Valves

Floating ball valves

A floating ball valve is an accessory of the valve machine as the ball is not supported, and it only moves in the main valve to seal the machine's pressure line. Its design is very magnificent and performance very well irrespective of any material like plastic or steel for the ball valve to move.

- Functions

- The most important function is that it is designed to stem and steal.

- The ball valve also seals off the pressure of any product by using soft seats.

- The ball valve gives its best performance with sealing off capacities.

- How it was a floating ball valve works

- The pressure works on the upper stream and also the backward side of the valves.

- The pressure makes the immense force downwards of the valves by make it move.

- This force results in sealing off plastic materials in the downstream seat.

- Advantages

- This floating ball valves offer long durability, where one can use it for many years.

- It comes under a variety of sizes, satisfying different variations of machines.

- These Ball valves can be used in a varied range of industrial application and is very versatile.

Gate valve

This valve is known for its flexibility of size as it requires a minimal space where any application can be operated. Its key feature is to eradicate the obstacles or barriers of the fluid, such as liquid or gas.

- How the gate valve works

- The first one needs to open the gate of the valve, and automatically fluid gets restricted.

- It works on two applications: the close gate and clockwise to close, which is CTC.

- The other application is CTO, which is clockwise to open for restriction of fluids

- Another important thing is to operate gate valves by inserting rectangular gates in the path where fluid flows.

- Advantages

- The sealing performance of the valve is better.

- It has a dual flow pipeline.

It is another type of valve machine where the surface is plain and flat, which provides on/off and regulates air movement by stopping the air from escaping through the valve.

- How it works-

- It has double operated cylinder.

- There is the steam pot's activation, which is known as SP, where the air is entered.

- There is also activation of SV, which is a slide valve where upper air pushes to SP.

- With this process, the steam air gets exhausted and get block by Slide Gate Valve.

- Advantages-

- The slide Gate is very affordable and very convenient to calculate.

- The total pressure loss in the machine is very minimum and does not cause much energy.

There are different types of Slide Gate valves, which are Knife plate, Standard, Solid wedges, Hulk plate, etc. You should know that all type of valves have their different usages depends upon their features and on their types.

Types and characteristics of industrial valves

Different manufacturing materials, different designs, applications, and variable uses ... industrial valves can be of very different types. The different sectors in which they are useful to demonstrate that these devices are extremely useful cover a myriad of different needs related to fluid management. In this article, you will know the main types of valves that exist, as well as their main characteristics and how they work.

These are the main types of industrial valves used today:

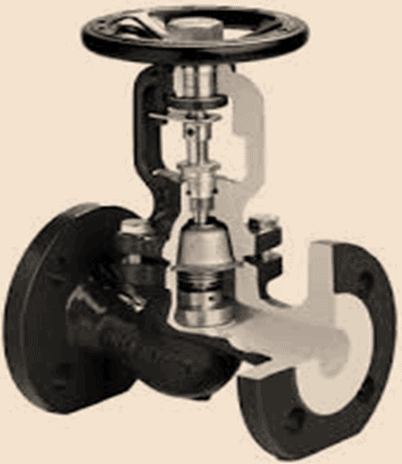

Globe valves. This device is used to control the flow of liquid in a pipeline. It is made up of a movable disc-type element and a stationary ring seat. The body is usually spherical in shape, although it is also shaped like a 'Y,' 'T,' or a balloon. These types of industrial valves are designed to offer complete tightness, as well as high flow effectiveness. They stand out for their durability, something related to the type of material in which they are.

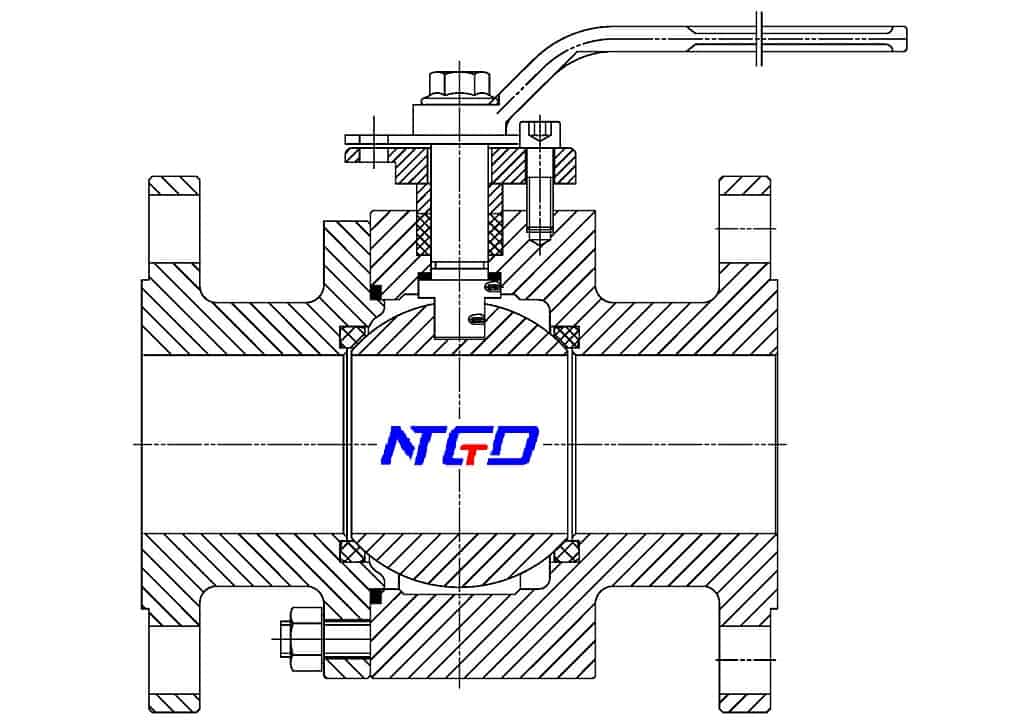

Ball or spherical valve. Also called ball valves, they are characterized by the fact that inside the house, a sphere with perforations through which one is produced to regulate the passage of fluids from the pipes. At the moment when the valve is in the closed position, the perforation is perpendicular to the inlet and outlet. However, when the ball valve is open, there is an alignment between the inlet and outlet of the valve itself. To easily distinguish the position of the device, a handle is used, which is used to manoeuvre with it. They can be operated manually or automatically and can have a one-piece, two or three-piece body. the non slam check valve is also good for industries.

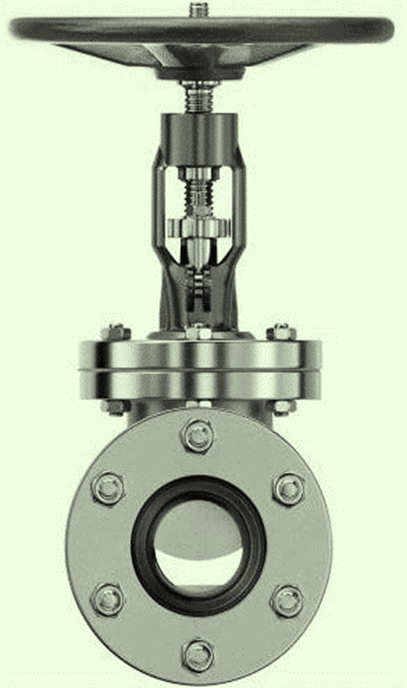

Gate valve. The procedure by which they open the way to a liquid is the raising of a blade or gate that can have rectangular or round shapes. They are not used for regulating, but for uninterrupted clean fluid flows. The opening and closing process causes frictional wear and is slow.

Needle valves. These valves facilitate efficient regulation of a high-pressure liquid for small pipes. They have a conical shaped closure shaft that acts as a plug-in a reduced opening. These valves are especially appreciated in the hydraulic sector, where they are used in bypasses, route cuts, and diversions as bypass, directing the flow to ball valves or butterfly valves as a previous step to introducing the liquid in turbines or engines. These valves are immune to strong contrasts between different pressures and have a good seal due to their design and stability. Bellows valve is also famous.

Butterfly valves. Useful to allow or prevent the passage of liquid. They have activated automatically or with actuators. These valves open with a 90º rotation of the disc. Globe valves are widely used.

Check valves. Also called non-return, check, or single flow, they close the flow of fluid in one direction and circulate in the opposite direction. One of the advantages it offers is that it prevents pump stripping and water hammer. There are several different types of check valves, such as swing flap valves, spring valves, ball check valves, and piston valves.